- Home

- Products

- Hang Tag Stringer

- High-Speed Automatic Hang Tag Stringing Machine, UM-HE3

High-Speed Automatic Hang Tag Stringing Machine, UM-HE3

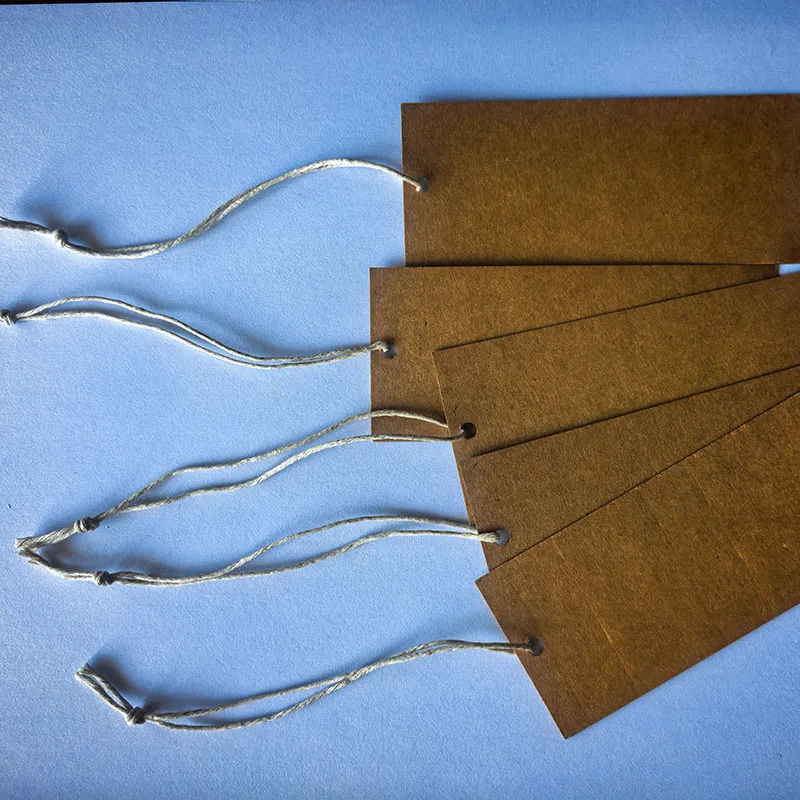

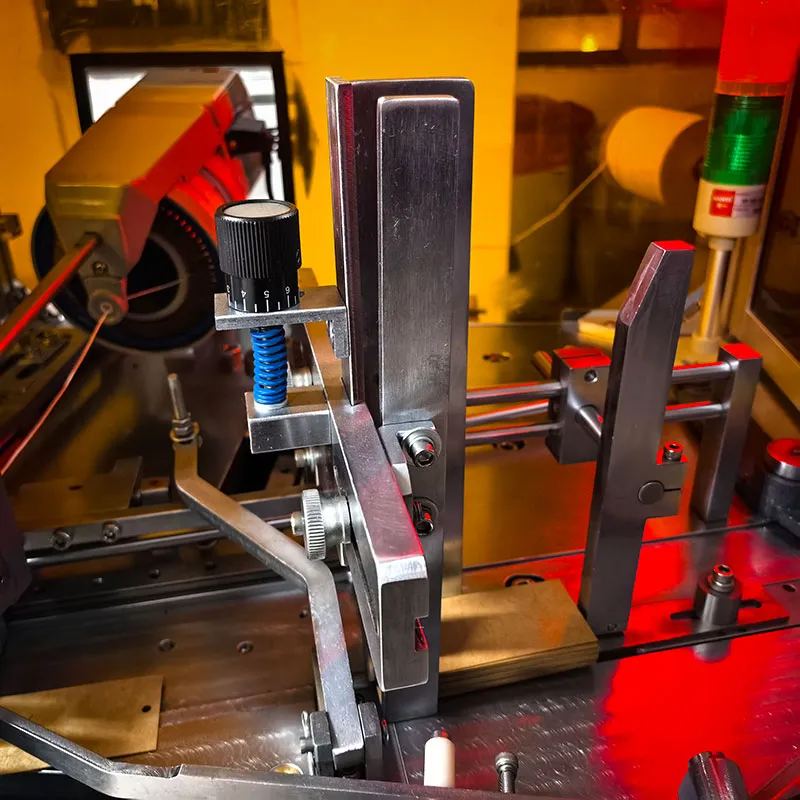

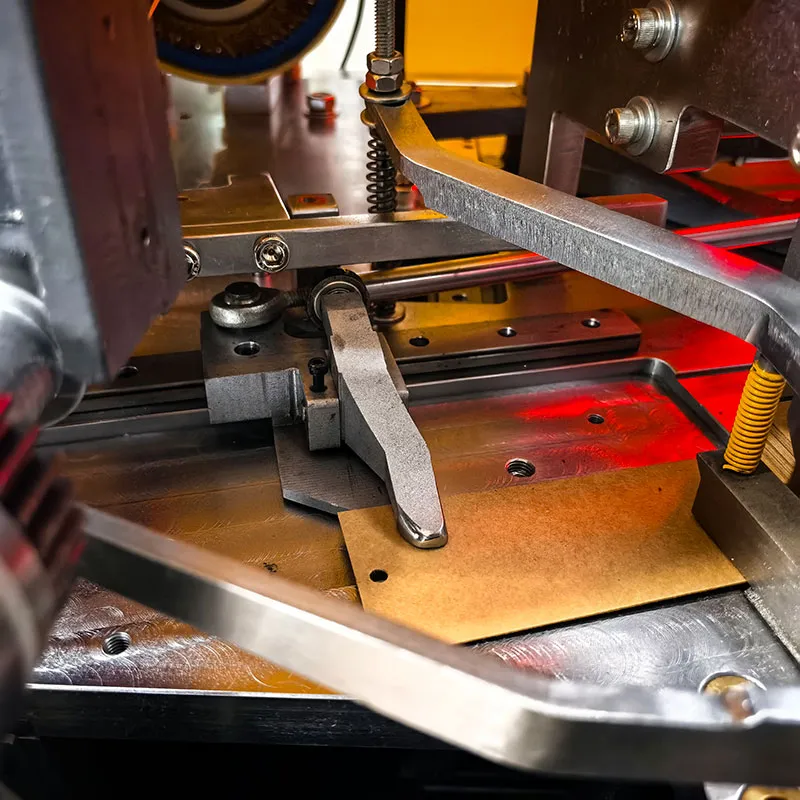

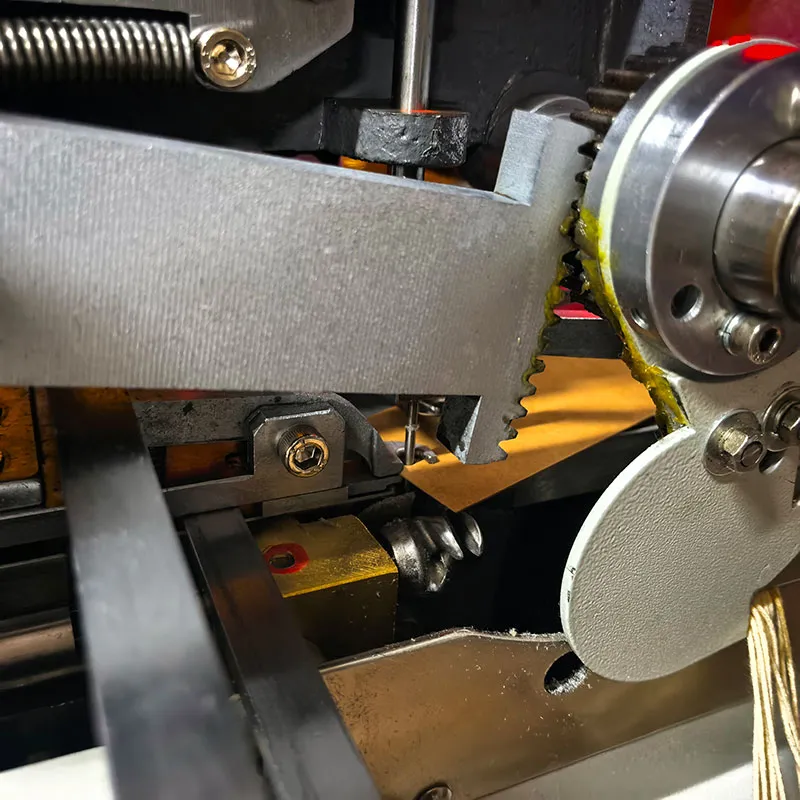

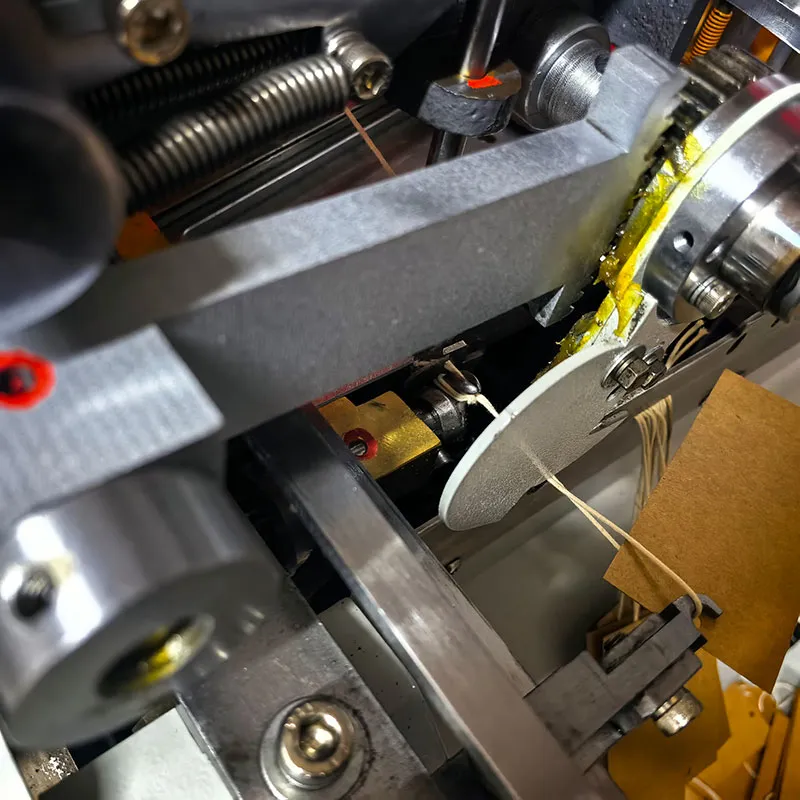

The high-speed automatic hang tag stringing machine is a standard model developed by our company, featuring a production speed of 4,000–6,000 pcs/hour. It is specifically designed for commonly used European- and American-style hang tags and can automatically perform tag loading, punching, stringing, knotting, and counting operations.

This stringing machine significantly improves production efficiency and is widely used in the production of hang tags for garments, accessories, bags, home textiles, shoes, hats, toys, sunglasses, kitchenware, wine, food, hair accessories, and other industries. It is easy to adjust and maintain, simple to operate, and effectively eliminates the inefficiencies associated with manual stringing, efficiently human error from manual stringing.

Configurations

The stringing machine is easy to operate and quick to learn, with the standard and optional configurations including: PLC system, touch screen, frequency inverter, sensors, servo motor, optional button control.

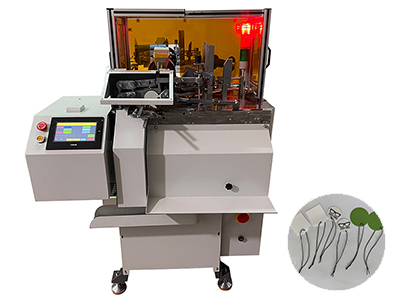

Applicable Hang Tag Shapes

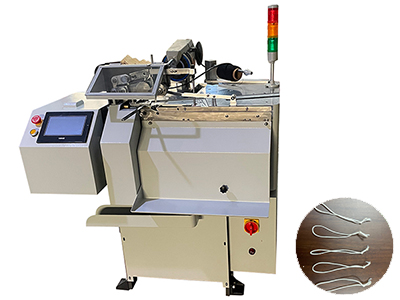

Hang Tag Production Process

Specifications of Hang Tag Stringing Machine

| Hang Tag Stringing Machine | |

| Model | UM-HE3 |

| Speed | 4000-6000pcs/hr |

| Cutting method | Cold cut |

| Weight | 450kg |

| Dimensions | 1050*1000*1400mm |

| Power supply | 220V, single phase, 50/60Hz |

| Power | 0.75kW |

| Hang Tag | |

| Tag material | Paper tag, plastic tag |

| Tag thickness | 180gsm-700gsm (for other thickness options, the machine is customizable per your sample) |

| Min. tag size | 20*35mm |

| Max. tag size | 90*150mm |

| Tag hole diameter | 3.0mm, 4.0mm, 5.0mm |

| Tag shape | Rectangle, square, round, oval, and other regular shapes |

| String thickness | 0.3-1.2mm |

| String material | Cotton string, gold thread, fiber string, nylon string, etc. |

| Knotted string working length | 80-200mm (tail is excluded) |

| Knotted string tail length | 15mm |

Automatic Operation vs Manual Operation (Hang Tag Stringing)

| Comparison Item | Automatic operation | Manual Operation | |

| Efficiency | Time | Speed | Speed |

| 1 minute | 100pcs | 12pcs | |

| 1 hour | 6,000pcs | 600pcs | |

| 10 hours | 60,000pcs | 5,500pcs | |

Note: The above figures are based on average values. If manual labor is required to achieve the same output as one machine, assuming a 10-hour working day, approximately 9–10 workers would be needed.

With over 15 years, UNIVERSAL MACHINERY has been specializing in supplying packaging machines including tag stringing

machine, tag-tying machine and eyeleting equipment. Our tag stringers are capable of providing high productivity for

punching, string, looping and knotting. Together with various options of automatic stringers, our experienced staff can

provide you right tag stringing solutions for your applications. We at UNIVERSAL MACHINERY aim to assist you in choosing

the right type of tag stringing machine to meet you or your customers’ requirements.

Inquiry

Other Products